Safety is paramount at Cherne Industries, especially when utilizing pneumatic pipe plugs. Contractors need to understand the equipment and work conditions to ensure optimum safety. Cherne’s high-quality pipe plugs are designed with safety in mind, but users must follow proper procedures to prevent accidents or mishaps.

Discover the top four safety tips for effectively utilizing Cherne's pneumatic pipe plugs in municipal or commercial pipeline testing, maintenance, and repair, ensuring a secure working environment. Always consult the product instruction manual provided with Cherne products for comprehensive guidelines on pipe plug usage.

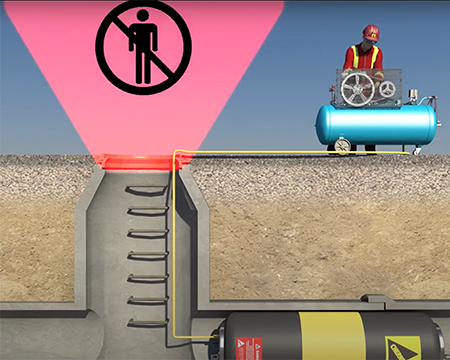

1. Never enter the danger zone

When a plug is in use, a danger zone expands outwardly in a cone shape from the manhole opening. The most important safety measure is never to enter this danger zone.

Remember that the total force exerted on a pipeline plug is directly proportional to both the pressure and the pipeline area. The amount of force behind a plug can be overwhelming.

To better understand the hidden dangers you may face when entering the danger zone, let’s break down what happens when a plug is used to hold back pressure.

The formula for calculating pipeline force is:

Force = Pipeline Area x Pressure

Consider the following examples: An 8-inch plug used in a 4 psi (pounds per square inch) test is subjected to over 250 pounds of force. The same 4 psi test in a 48-inch diameter pipe is restraining over 7,200 pounds of force. Standing in front of a plug during this type of air test would be like standing in front of a loaded cannon with a lit fuse. A plug deflated before the back pressure is released can cause serious injury and even death.

2. Preparation before using pipe plugs

Before beginning any job, follow the guidelines below to prepare for using pneumatic pipe plugs.

Select the proper plug and related equipment. Every pipe plug has performance specifications listed on it and in the product literature.

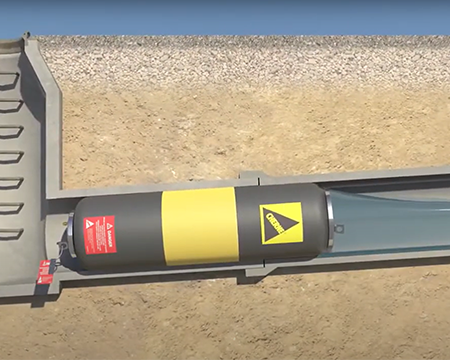

- Determine the back pressure: The maximum back pressure the plug must withstand is the pressure (air or liquid) in front or back of the plug that it must restrain. Never exceed the plug’s back pressure rating. As explained in the previous section, the total force exerted on a pipeline plug is directly proportional to both the pressure and the pipeline area.

- Select the correct plug size: Pipe plugs have a minimum and maximum sealing size range. Always verify that the pipe inside diameter (I.D.) is within the plug’s sealing (usage) range. It’s essential to check the I.D. of the pipe to be plugged in and match it to the pneumatic plug’s usage range to ensure it will work in the intended pipe.

- Correct pipe design: Plug performance could vary depending on pipe types. For example, the plug’s back pressure rating drops by 50% in corrugated pipes.

- Use calibrated gauges: Failure to use calibrated gauges could result in plug over-inflation or under-inflation, leading to failure. We recommend monitoring inflation and back pressure with calibrated pressure gauges only. In addition, never deflate a plug while back pressure is still in the line. More importantly, always deflate a plug remotely using an extension hose. Once again, never deflate a plug within the danger zone.

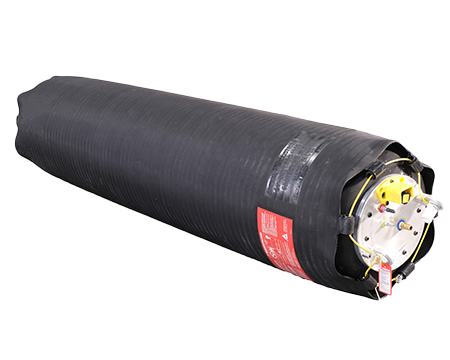

- Properly clean and inspect the plugs: Plugs must be cleaned and inspected before and after every use. Do not use a plug if it shows any signs of wear or deterioration.

The inspection should include, but not be limited to, looking for cuts, abrasions, punctures, bulges, cracks, corrosion, loose or damaged fittings and components, and leaks.

Be sure to inspect the pipe and clear it of debris or foreign substances before placing the plug in it. Inflation against a sharp object could cause the plug to rupture. An unclean pipe could reduce the plug’s back pressure-holding capability and damage it during placement or inflation.

An engineer must determine if a backup system is required and design a blocking device. An additional backup system should be considered to prevent injury or property damage in case of plug failure. A properly designed blocking device must be used to restrain any plug movement because the forces behind the plug could be tremendous. Never use eye bolts, inflation hoses, or other attachments on the plug to restrain plug movement under back pressure.

3. Monitor the placement and pressure of the plug during operation

While in operation, it is important to monitor the placement and pressure of the plugs.

Never use chemicals, including hydrocarbons, as they can damage natural rubber. Be sure to use the correct media when inflating the plugs. Cherne plugs can be inflated with air, water, and inert gasses (nitrogen). Never over-inflate or under-inflate the plugs.

Always release the back pressure from the pipe before deflating the plug. Plug deflation before releasing back pressure could cause the plug to dislodge at extreme velocity.

4. Maintenance and storage

Cherne’s pneumatic plugs can be cleaned with mild soap and water. (Other cleaning agents may damage them.) Store the plug in a dry place, below 110 degrees Fahrenheit, away from sunlight or other sources of ultraviolet light and ozone.

Following these simple steps and taking the time to perform the procedure correctly can make the difference between life and death. Cherne provides safety tags and safety instruction manuals with each plug that leaves our factory. Ensure that you and everyone on your crew are familiar with the hazards and preventive measures necessary when working with pipe plugs.