When embarking on projects involving PVC pipes, you might encounter frequent references to the process of chamfering in various guides, manuals, and instructional videos. This term points to a preparatory step that, while seemingly minor, significantly impacts the integrity and outcome of PVC pipe fitting work.

Chamfering is a cornerstone technique that prepares the pipe for a secure and precise fit by creating a smooth, angled cut along the end rim of a PVC pipe.

By acknowledging and implementing this critical step, individuals can avoid common pitfalls and achieve a higher standard in their plumbing and construction projects. Chamfering is not just a technical requirement but a critical best practice that boosts the success rate and operational efficiency of PVC pipe installations.

The Role of Chamfering in PVC Pipe Fittings

Chamfering plays a vital role in plumbing, particularly drain lines and water pipes in residential and commercial buildings. The process facilitates smoother installation and reduces the likelihood of blockages and damage within the plumbing system.

When materials get stuck in the drain line after the first flush of a toilet, it underscores the importance of ensuring that all connections and pipe ends are smoothly transitioned. Chamfering the edges of pipes before they are connected can significantly reduce the risk of material catching and building up at the joints, thus minimizing potential blockages.

For water pipes, chamfering can help prevent debris accumulation by allowing materials to flow more freely through the system, reducing the chances of clogs in aerators, appliances, or even industrial machinery. Smooth, chamfered joints are also more resistant to the stresses caused by water hammer or sustained high pressure, which can otherwise lead to joint failure, pipe separation, and the catastrophic open water pipe scenarios described earlier.

Chamfering becomes even more critical in multi-story buildings where the consequences of plumbing failures can escalate quickly. Properly chamfered pipe ends facilitate a more reliable plumbing system that can withstand the demands of higher pressures and usage levels. This will ultimately protect the infrastructure from the exponential damage that water leaks and failures can cause.

What Happens If You Don't Chamfer a Pipe?

- Assembly challenges: Without chamfering, inserting the pipe into the fitting can scrape the cement off during assembly, risking insecure or unsealed connections. This threatens the structural integrity of the pipe and joint.

- Debris accumulation and blockages: Over time, sediment and waste can collect around burrs, leading to significant blockages and reduced flow, putting extra strain on the plumbing system. When the fitting is scraped, the cement creates a dam effect that catches debris.

- Maintenance costs: Neglecting the chamfering process can result in frequent maintenance, drainage issues, or inefficient water delivery.

In short, chamfering is a preventive measure vital for a durable and efficient plumbing system and especially crucial in larger, multi-story, commercial, and industrial buildings.

How to Chamfer PVC Pipes

Chamfering might sound complex, but it can be a straightforward process with the right tools and approach. Here’s how to do it:

1. Gather your tools and materials:

- Deburring tool or file: A deburring tool is specifically designed to smooth the rough edges of cut pipes. For PVC pipes, a deburring tool easily removes burrs and sharp edges, creating the smooth and beveled finish required for a proper connection. A fine-toothed file can be an effective alternative if a deburring tool isn't available. While using a file may require more effort and time, it can still achieve the desired chamfered edge by manually filing around the circumference of the pipe.

- Safety gear (gloves and goggles): Safety should never be overlooked when working with any tools, even for seemingly simple tasks like chamfering PVC pipes. Gloves protect your hands from sharp edges created during the cutting and chamfering process, reducing the risk of cuts or abrasions. Goggles are essential to guard your eyes against small PVC shavings or particles that might become airborne during chamfering. These particles can cause eye irritation or injury; hence, the importance of protective eyewear.

Oatey Tip: Before you start chamfering, measure and mark the area you need to bevel. A standard recommendation is to chamfer the pipe end to about 10 to 15% of the pipe’s wall thickness. This measurement ensures enough material is removed to create a smooth edge without compromising the pipe’s strength.

2. Create the Chamfer

Using a deburring tool or file, begin removing material from the outer edge of the pipe at an angle. Work your way around the pipe, maintaining a consistent angle and pressure. The goal is to create a uniform beveled edge around the entire circumference.

After chamfering, inspect the edge to ensure it’s even and smooth. Run your fingers along the edge to check for any rough spots or burrs. If needed, use a file or sandpaper to smooth out any irregularities.

3. Clean the Pipe and Fitting

Once you’ve chamfered the pipe, clean and prime the surface before applying solvent cement, this essential step removes any dust or debris, while priming prepares the surface for a strong bond.

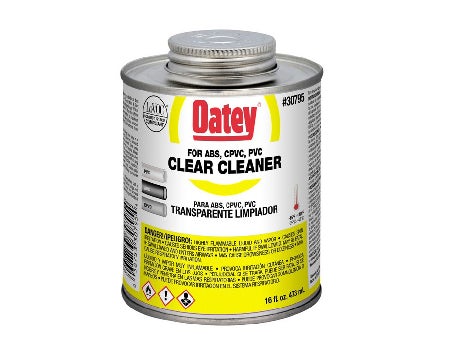

Products like Oatey® Clear Cleaner ensure the pipes are ready for the next step. Formulated for all schedules and diameters of ABS, PVC and CPVC pipe and fittings, Oatey® Clear Cleaner has a clear finish that flows freely, evaporates quickly, and will not stain most surfaces. It applies easily with its included in-lid dauber.

If you are looking to solvent weld PVC, ABS, or CPVC pipes and fittings after chamfering a pipe, look at this guide on how to achieve a perfect solvent cement joint every time.

Oatey Tip: Even with careful attention, mistakes can happen during chamfering. Common errors include creating an uneven bevel or removing too much material. To avoid these issues, practice using scrap pieces of PVC before working on your main project. This practice helps you develop the feel and technique necessary for successful chamfering.

Chamfering PVC pipes is critical in ensuring successful and long-lasting plumbing connections. By taking the time to chamfer, you improve the efficiency and reliability of your joints, preventing leaks and blockages that can lead to costly repairs. Whether you’re a beginner or a seasoned pro, mastering the art of chamfering will elevate your plumbing projects.