Solvent welding large-diameter PVC, ABS, or CPVC pipes might seem daunting, especially given the scale and the materials involved. However, it can be a straightforward and manageable process with the right preparation, tools, and techniques. Proper surface cleaning, choosing the correct solvent cement, and allowing adequate cure time are critical steps that can significantly influence the quality of the joint.

Whether you’re a seasoned plumber or a construction professional, these five valuable tips will help ensure a secure connection. Remember, taking the time to understand the properties of the materials and the specifics of the welding process can lead to successful outcomes every time.

Note: Oatey considers pipes to be large-diameter if they are 150mm (six inches) or greater.

1. Use the Proper Tools and Practices When Preparing the Pipe

Proper pipe preparation before a solvent weld reduces the chance of pipe-connection failures. Prepping a large pipe involves cutting, deburring, chamfering, and cleaning it.

- Cutting: We recommend using a pipe wrap to produce an accurate line to follow when cutting. This will create a pipe end that is “squarely” cut, which ensures maximum surface area to create fusion, joint strength, and the strongest bond.

- Deburring: After cutting the pipe, a rough area of burr may form around the inside edge. Using a deburring tool will remove the burr and polish the edges of the pipe for a smooth finish. If you skip this step, pieces of plastic can break free and move through the system, leading to blockages.

- Chamfering: The next step is to chamfer the outside ends of the pipe. Chamfering removes the pipe's sharp outside edge at a minimum of 3/32 inches, equal to a 10—to 15-degree angle. Chamfering the outside is important to streamline assembly and ensure leak-free joints.

You can use a portable or stationary chamfering machine, a hand grinder, or a router bit. We recommend assessing all the potential safety hazards on site before choosing the best pipe chamfering method for your job.

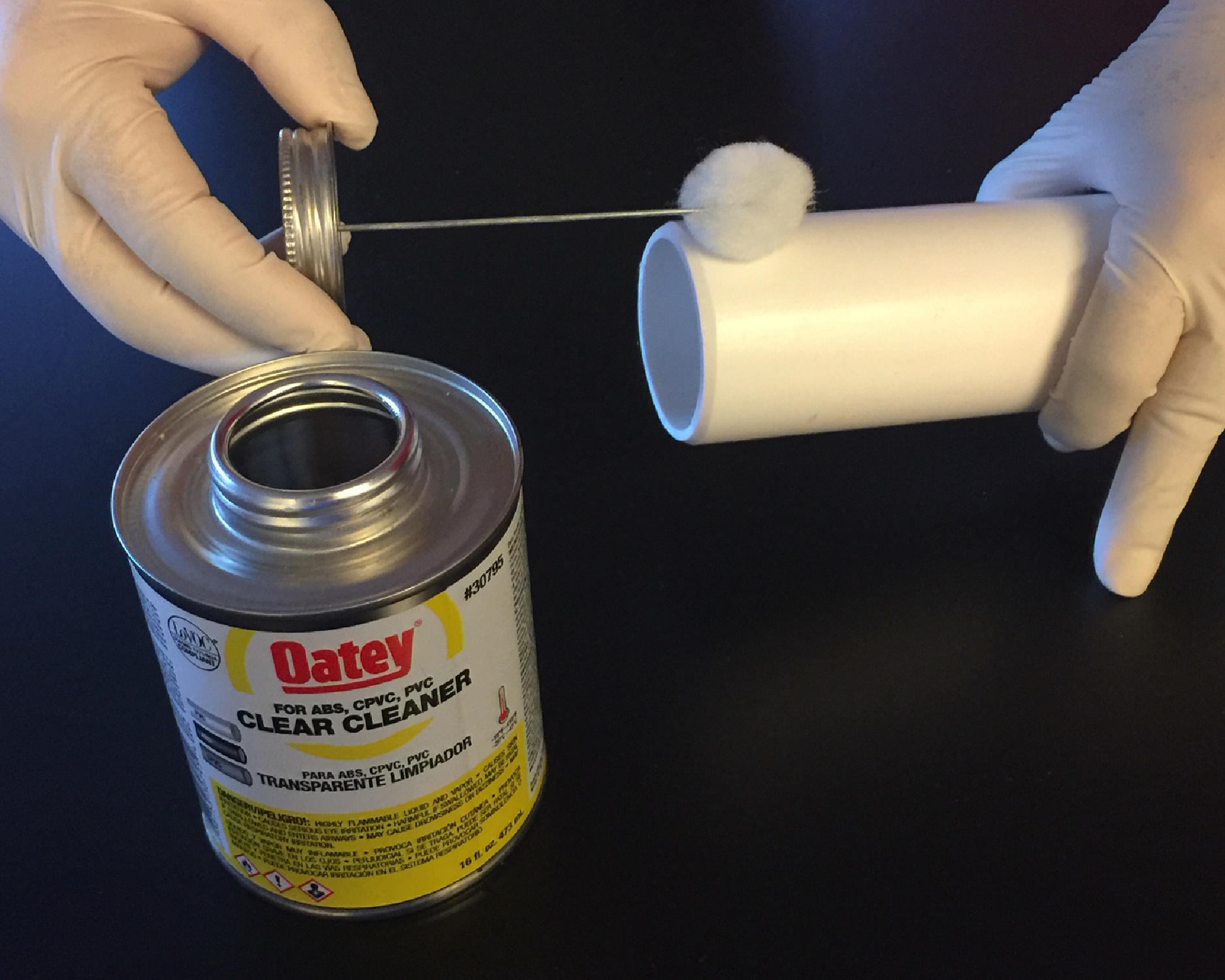

- Cleaning: The final step is to clean off any dirt or grease that may have gotten on the pipe edge. This is important before applying the primer and cement so nothing interferes with the application. You can use Oatey Clear Cleaner on all ABS, PVC, and CPVC pipes and fittings.

2. Select the Right Primer and Cement for the Job

Use primers to ensure a fast, secure solvent weld for large-diameter PVC and CPVC piping systems. Oatey Industrial Grade Primer removes contaminants and softens the pipe surface.

You won’t create the proper weld you need if you use the wrong solvent cement. Your choice should be based on the three key factors: pipe material, size, and job conditions.

- If you are working with CPVC pipe fittings, use CPVC cement.

- For PVC, use PVC cement.

- For ABS, use ABS cement.

The larger the pipe, the thicker the viscosity of the cement you will need. We recommend using:

- medium-body cement if your pipe is up to six inches in diameter;

- heavy-body cement if your pipe is over eight inches in diameter.

Oatey offers heavy-duty cement (PVC) that covers up to 12-inch pressure pipe and 18-inch non-pressure, heavy-duty cement (CPVC) that covers up to 12-inch pressure and 14-inch non-pressure.

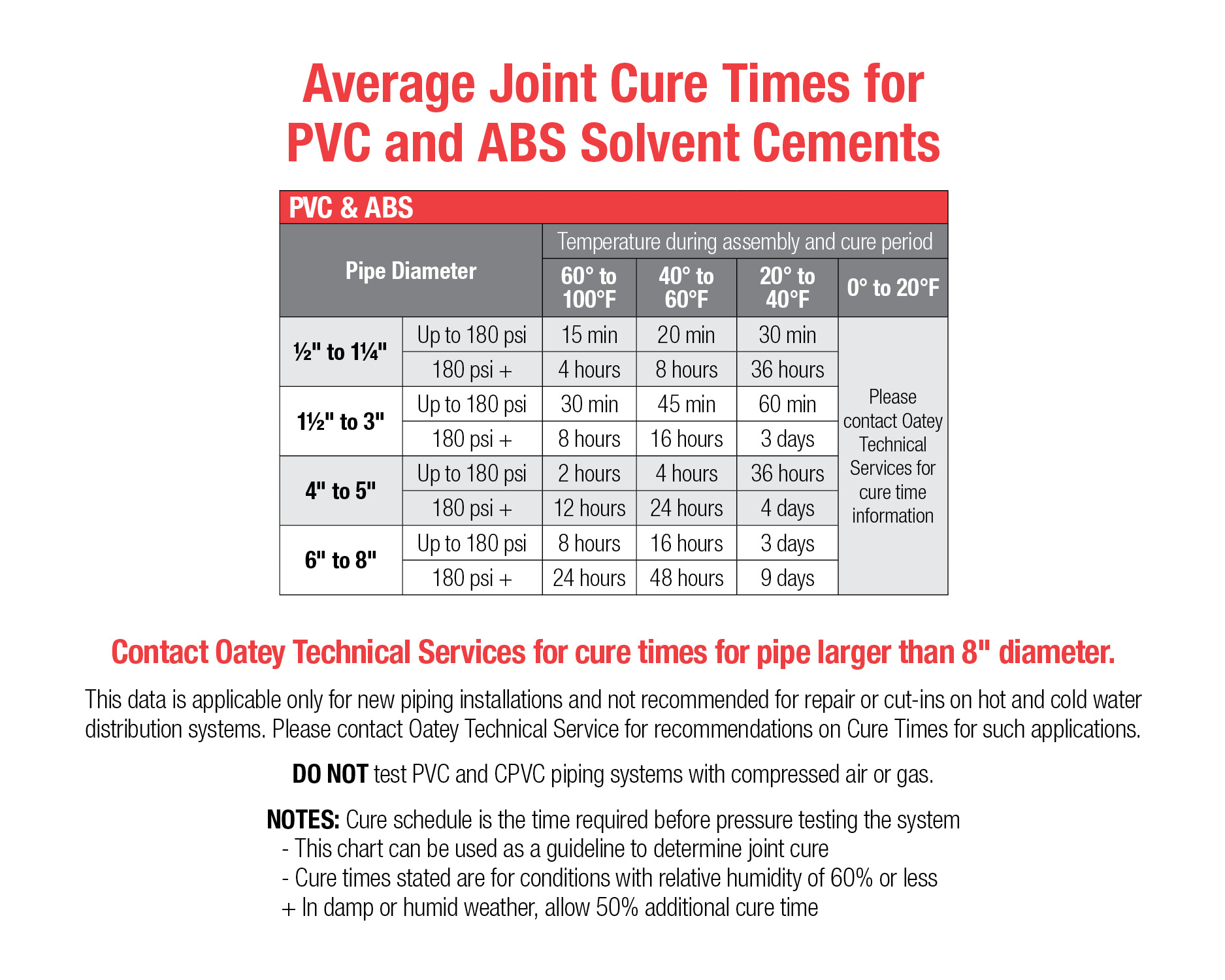

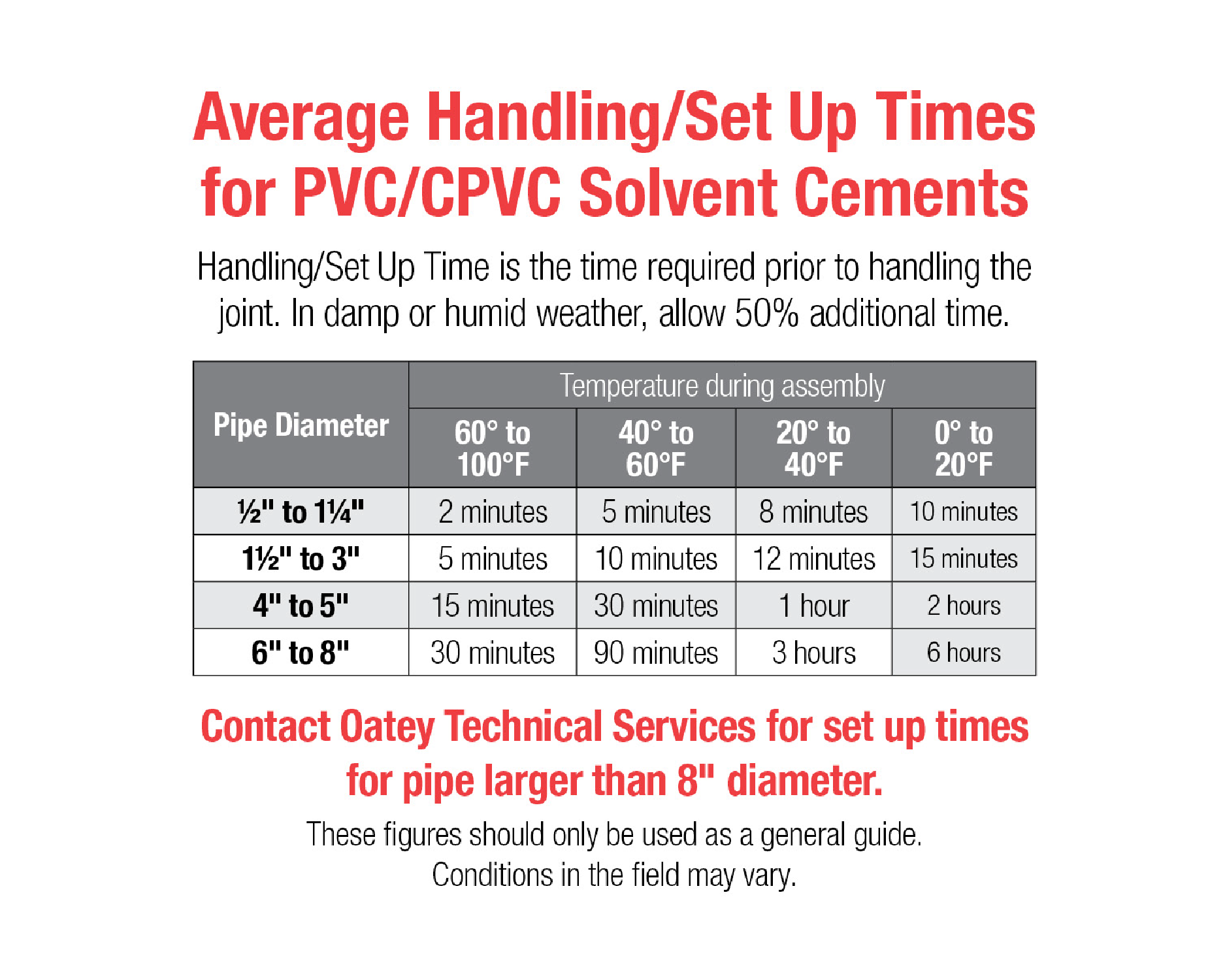

You must also consider the cure time once the assembly is in place. You can view our complete instructions on solvent welding using Oatey cement types. You can also find our recommended cure time chart below, based on pipe diameter and temperature during assembly.

Contact Oatey Technical Support for cure times for pipe diameters larger than eight inches.

3. Use the Proper Tool for Cement Application

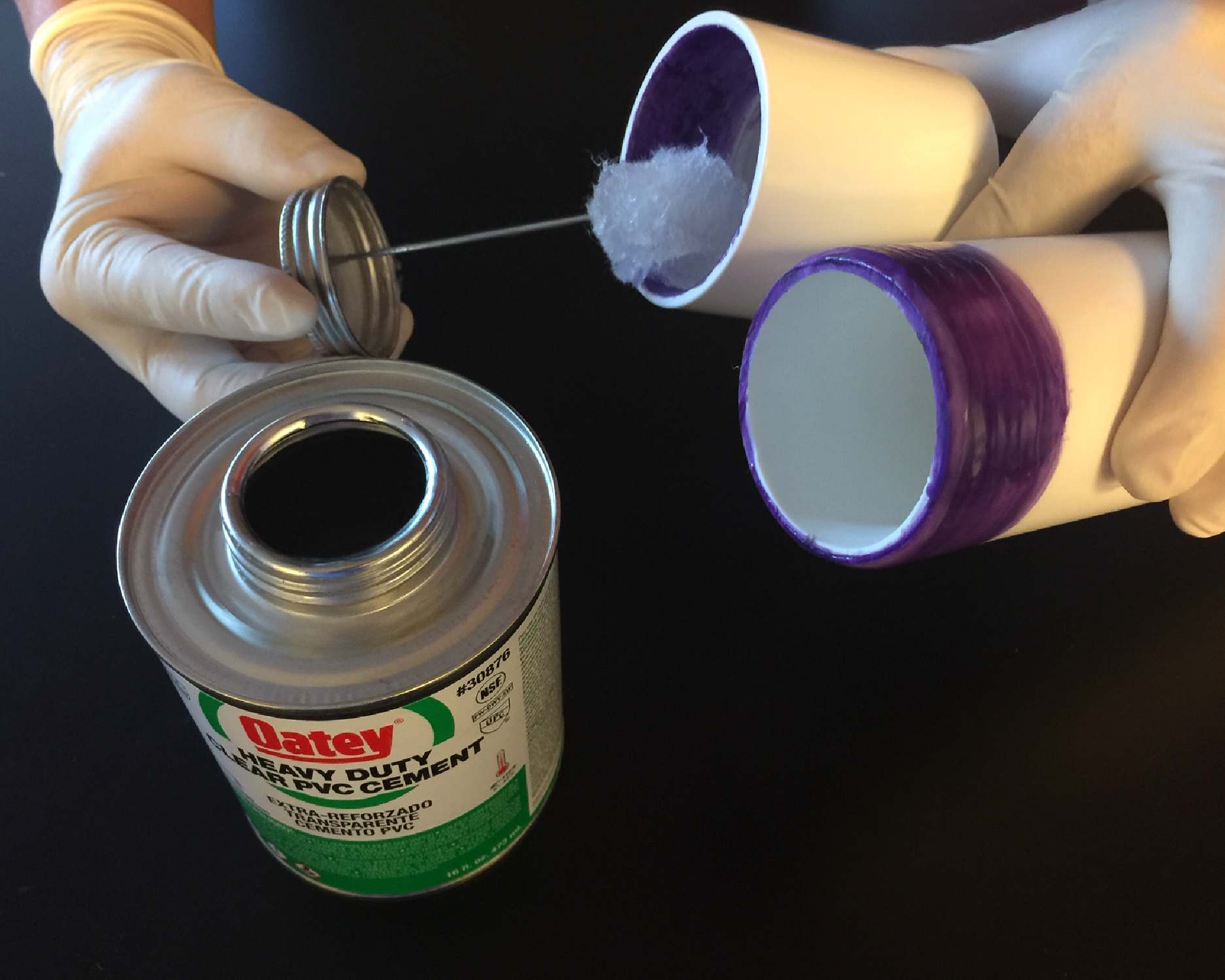

Before opening any cement containers, give them a good shake. If the container sits for too long, the solids can separate in some of the thicker cement types. Once you have a good uniform mixture, apply it to the pipe using a swab or roller.

To apply the cement evenly, you’ll want to use the tool most suited to the pipe size. According to the ASTM standard, your swab or roller should be half the size of the pipe diameter.

- We recommend using a swab when handling pipes up to six inches. For a six-inch pipe, you should use a three-inch swab.

- Use a roller for anything larger than six inches.

Oatey offers rollers and swabs up to 12 inches in length so that you can be sure of a proper application.

4. Multiple Installers + Specialized Mechanical Tool = Secure Connection

Since you will be working with heavier pipes, be sure to have additional help aligning and creating the connection. If the pipe is not properly connected, it could fail, leak, or be off-measured.

Multiple people and a mechanical joining tool should be used to produce an accurate and secure solvent weld. You’ll want to position yourself, the pipe, and the fittings to ensure proper joint alignment during installation.

Using a mechanical pipe puller will safely and cleanly join the large-diameter pipes and seat them completely for a true connection. The finished joint must not be disturbed for the recommended setup time.

Oatey does not recommend using heavy equipment, like a backhoe, as it could cause severe damage to the pipe and fittings.

5. Prefabricate Whatever You Can

Having multiple people prep and work on the pipe will help cut down on time so you can get the connection together as quickly as possible. We recommend assembling any joints beforehand to make your job easier.

Take, for example, an underground job: Here, you can assemble the large pipe out of the trench ahead of time and then lower it into the trench to reduce the number of connections you’ll need to make in the smaller space below ground.

Similarly, if you are going through multiple floors, assemble as many pieces as possible before feeding them up. That way, you will not have to work in a cramped space.

Working with a large-diameter pipe for solvent welding need not be complicated. It all comes down to using the right tools for the welding material and following the correct procedures, which will ensure a secure connection.

Watch our video here to get our best tips for creating the perfect solvent weld.