Soldering, a process commonly used by plumbers, involves melting a filler metal (a.k.a. solder) to join two or more metal components. As a plumber or plumbing apprentice, you need to understand the different types of soldering techniques and materials to ensure a successful joint.

This blog post will give you a detailed guide on the different types of solder, essential tools and materials, safety precautions, and how to solder copper pipes. After you’ve finished reading this blog, we are confident you will be on your way to soldering like a pro.

What Is Solder?

Solder is an alloy of different types of metals, which change depending on the application. Traditionally, solder was made from lead. However, since regulatory bodies have become aware of the adverse effects of lead in potable water systems, we no longer use lead solders for potable water applications. Nonetheless, lead solder is still used and preferred in some applications.

Solder is used on many materials, including brass, copper, and galvanized steel. For plumbing applications, copper pipes and brass fittings are most commonly used in water supply lines.

What is Soldering?

As noted, soldering is a bonding technique in which molten solder joins two metallic surfaces by applying a melted filler metal (solder) to the joint. As the solder cools, it solidifies, producing a solid mechanical bond.

When soldering pipes, valves, and fittings in a plumbing application, it is essential to produce air-tight and water-tight connections that withstand high pressure and temperature. This process can involve different types of solder in one of three techniques: soft soldering, hard soldering, and brazing.

The solder type needed will depend on the application. Use the most appropriate type for your specific project, and be mindful that certain solders are unsafe for drinking water.

Lead-free solder is environmentally friendly, while lead-based solder is more affordable and easier to use. Silver-based solder is used in high-strength applications where durability is critical.

Solder for potable water

Always use solders made from lead-free alloys for potable water systems. We recommend the Oatey® 95/5 and the Oatey® Safe-Flo® solders. Both are 100% lead-free and, therefore, suitable for drinking water applications, refrigeration lines, or cooling equipment.

Oatey® 97/3 is a tin-copper alloy. Due to its higher melting point, this combination is perfect for sweating copper and brass plumbing joints.

Solder for galvanized steel and electrical work

Oatey® Acid Core Wire Solder and Oatey® Rosin Core Wire Solder are 2-in-1 solutions that combine the solder with an acid or rosin flux core.

By combining the flux with the solder, installers can save time and money, avoid common mistakes, and ensure even application of flux and solder as they climb the learning curve to achieve a perfect solder.

These hybrids are typically used for general-purpose repairs. Acid core solder is perfect for repairing galvanized gutters and filling metal seams. Rosin core solder is used in electrical applications, including wiring and other fine electronic work.

Lead solders

Although heavily scrutinized, lead solders remain safe for applications not intended for human consumption. Like the acid and rosin core solders, some lead solders contain a flux core, usually in a 50/50 or a 40/60 metal-lead composition. As a result, these solders have lower melting temperatures and flow easier than newer solders.

Oatey® Bar Solder is a general-purpose alloy of 50% tin and 50% lead. This solder is designed for tin plating, seaming joints, and sheet metal.

How to Solder: Tips to solder joints or pipes successfully

Now that you understand solder and soldering, you may be wondering about proper techniques. Once you have all the tools to achieve a perfect solder, the general steps are to prepare materials, heat the joint, apply solder to the joint, and cool and inspect the soldered joint.

However, before starting the soldering process, avoid these five common mistakes for a leak-free joint.

1. Gather your materials

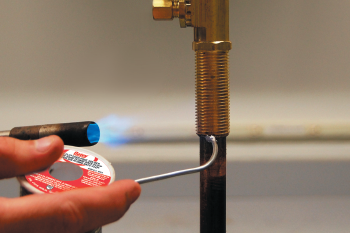

As previously discussed, you must determine the solder type necessary for your application. Once you know the appropriate solder, decide which flux and pipe-cleaning tools you need. Learn more about pipe cleaning and flux in sections three and four.

2. Wear protective gear

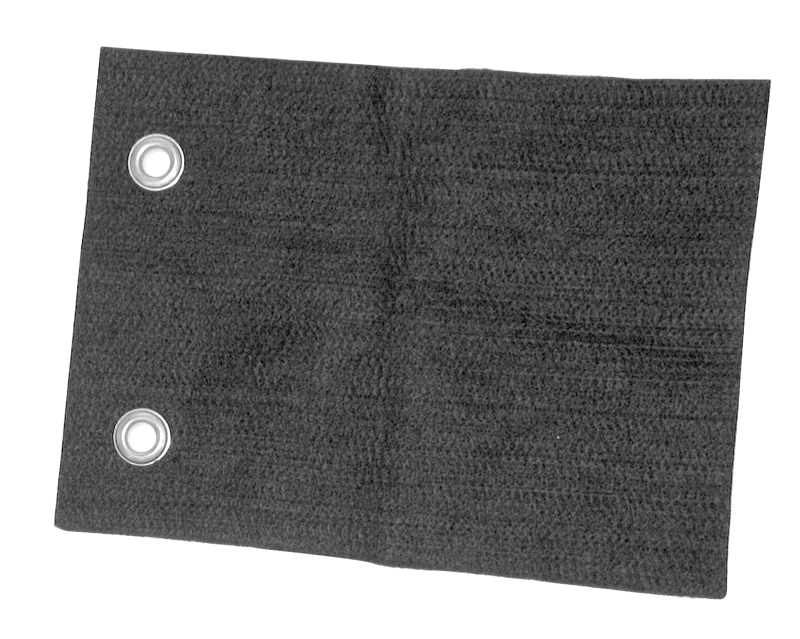

During the soldering process, you will be exposed to fire, chemicals, and molten metals. Oatey recommends wearing the proper personal protective equipment to ensure optimal safety: gloves and goggles, as well as using flame-retardant materials, like Masters® Flame Protector.

Oatey Flame Protector is a non-asbestos flame-retardant cloth that protects studs, walls, floors, and other surfaces from flames and sparks when soldering. Made of oxidized polyacrylonitrile (OPAN) fibers, this cloth offers heat protection of up to 2,282° Fahrenheit, making it ideal for use with higher-temperature torches, including propane and MAPP gas. Brass eyelets allow for easy hanging from a stud or wall.

3. Clean the pipe and fitting

To create a better bond, make sure you apply flux onto a clean surface. First, use a sand cloth or abrasive mesh to remove dirt and oxidation from the pipe. You can also clean the inside of the fitting by inserting a fitting brush and twisting it to scour the inside and remove oxidation.

4. Apply flux

Flux is an essential wetting agent that, once heated up, will help direct the molten solder to flow into the fitting cup.

Using a thin acid brush or flux brush, apply a light coating to the end of the pipe and the inside of the fitting. Then, immediately join the two together and wipe off the excess.

You will want to avoid using too much flux, which will cause the solder to run down the pipe once heated.

Types of Fluxes

The flux type you select will depend on the project type and your experience level. Acid fluxes are petroleum-based, formulated to prevent copper piping from turning green, and are excellent for large-diameter copper pipe applications. Oatey® No. 5 Paste Flux is a petrolatum-based flux designed to provide superior wetting properties for better solder flow. It can be used with most soft solders, 100% lead-free and safe for use on potable water applications.

For beginners, Oatey recommends opting for a tinning flux with ground-up solder in the flux, making it a great primer. Masters®Tinning Flux is a good option if your project requires working with larger pipes. Typically, large pipes have a greater chance of error than smaller ones, but tinning flux ensures the fitting cup fills once you begin soldering.

If you use a petrolatum-based tinning flux, which is not water-soluble, flush the line with a trisodium phosphate cleaner.

Oatey also offers a line of water-soluble fluxes, such as the Oatey®H-20®5 Paste Flux, which removes the need to flush your system with a special solution after installation. All you need to do is run water through your system for a few minutes after the soldered joint is cooled to remove any additional flux from the pipe’s interior.

5. Heat to the temperature required for soldering

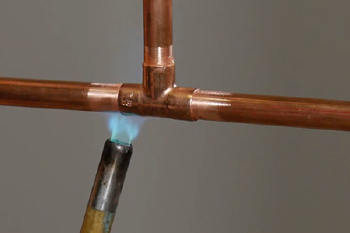

To solder, you will need a torch to apply heat to the joint. Start on one side at a 45-degree angle and begin touching the solder to the joint. Once the solder melts, flip the flame to the other side, again holding the torch at a 45-degree angle. Run the melting solder along the seam between the pipe and fitting. You will know the fitting cup is loaded when the solder begins dropping.

Important Note: Avoid overheating the joint. Excess heat not only can damage the fitting, but also cause the flux to burn, which impedes the solder from flowing into the fitting cup. Oatey recommends heating until the solder just begins flowing.

To avoid overheating, we recommend that for small-diameter piping, you direct the heat near the joint. For large-diameter piping, move the heat around the joint to ensure adequate solder flow around its circumference.

Certain low-lead materials, such as brass, do not conduct heat as well. To combat this, we recommend heating the pipe a little outside the hub or directly at the joint until the flux bubbles or activates. Then, apply heat to the base of the fitting. In addition, be sure to use a tinning flux with low-lead materials.

For more information on soldering low-lead pipes, read our blog on how to expertly solder low-lead pipes.

6. Cool, inspect, and clean

Once the soldered joints are thoroughly cool, examine each to ensure it is smooth, consistent, and free of any flaws. Use warm water and soap to remove any excess flux from the pipe. Due to its acid content, excess flux will continue eating away at the pipe, causing it to patinate.

For further guidance on soldering techniques, check out our video tutorial on How To Solder Copper Pipes.