Plumbing maintenance might not be the most exciting DIY project, but it’s essential for the smooth functioning of our homes. Plumbing grease can play a pivotal role in maintaining the integrity and functionality of your plumbing system.

Whether tackling a leaky faucet, installing new fixtures, or undertaking more extensive plumbing projects, the proper grease can make all the difference. From preventing corrosion to ensuring smooth operation, plumbing grease is a vital lubricant and sealant in various plumbing applications.

This guide will delve deeper into what plumbing grease is, explore its applications, and offer advice on selecting the appropriate type for your needs.

What Is Plumbing Grease?

Plumbing grease, also known as plumber’s grease or silicone grease, is a lubricant formulated for plumbing systems. It is typically made of silicone oil or petroleum-based substances mixed with a thickening agent. This combination creates a viscous and adhesive substance perfect for coating and protecting plumbing components from moisture, corrosion, and wear.

Why Does Proper Lubrication Matter in Plumbing?

One of the primary benefits of plumbing grease is that it shields metal fixtures and fittings from corrosion. It also ensures that seals remain tight, valves open and close as they should, and faucets don’t seize up.

Consistent lubrication reduces joint failure in two main ways. First, it mitigates the wear and tear that occurs with every movement, twist, or push of these parts. Second, it forms a protective barrier that prevents water from corroding your fixtures' surfaces. This action effectively increases the longevity of your plumbing systems.

Types of Plumbing Greases

Plumbing greases aren’t one-size-fits-all. There are various formulations, each tailored to specific applications and materials. Understanding the differences among them is critical to achieving the best results.

1. Silicone-Based

Silicone grease is commonly used in plumbing due to its compatibility with plastics and rubber. It’s the go-to option for elements in contact with potable water systems. Silicone greases are nontoxic, nonhazardous, and can withstand various temperatures. They’re perfect for faucet valves, rubber washers, and O-rings.

- Hercules® Plumber’s Silicone Grease is a high-performance, silicone-based lubricant for various plumbing applications. Safe for use with potable water systems, this grease lubricates O-rings, faucets, and valve stems, providing long-lasting protection against corrosion, rust, and wear.

2. Petroleum-Based

Petroleum-based plumbing grease is the workhorse of the plumbing world. It’s generally stronger and longer-lasting than silicone, but it comes with a major caveat: It’s not universal. Petroleum-based grease can degrade rubber and plastic over time. Petroleum-based plumbing greases are used in applications where metal meets metal, and the lubrication demands are extreme.

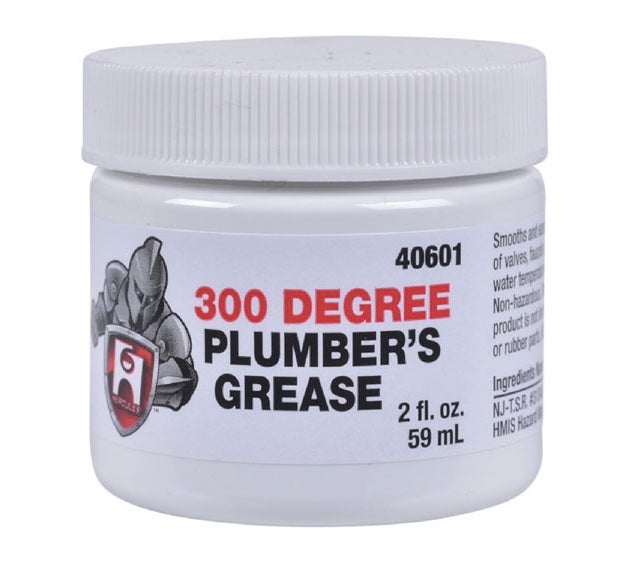

- Hercules® 300 Degree Plumber’s Grease is specifically formulated for high-temperature applications and can withstand up to 300°F. This petroleum-based grease is perfect for metal-to-metal connections, ensuring smooth operation and preventing corrosion and seizing in extreme conditions.

3. All-Purpose Lubricants

All-purpose pipe lubricants combine the advantages of silicone and petroleum grease into a versatile formula. Made of a blend of mixed fatty acid soap in a base of glycols and water solvents with clay pigment filler, they can be used over a wide temperature range, from -10°F to 150°F.

These lubricants are ideal for assembling pipelines made from cast iron, concrete, plastic, clay, and natural or synthetic rubbers. Professionals more commonly use all-purpose lubricants for larger applications or small motors.

- Oatey® All Purpose Pipe Lubricant is a nontoxic, noncorrosive grease that simplifies installing and repairing O-rings, gaskets, and pipes. Its water-soluble formula ensures easy cleanup and is ideal for various plumbing tasks, supporting smooth assembly and disassembly of pipe joints and fittings.

- MASTERS® Lubricating Oiler with Flex Spout, is a premium, all-purpose, petroleum-based lubricant that protects metal parts. This product is a must-have for restoring the easy operation of older plumbing systems and is excellent for loosening rusted or frozen fittings.

Selecting The Correct Plumbing Grease

Selecting the appropriate plumbing grease for your specific application ensures optimal plumbing system performance. When choosing the proper grease, make sure you consider the following factors:

1. Temperature

Plumbing systems often encounter extreme temperatures, ranging from bitter cold to scorching heat. Greases with a broad temperature range offer versatility and reliability, maintaining their effectiveness across various seasons and weather conditions.

2. Material Compatibility

Another crucial factor to consider is material compatibility. Plumbing fixtures and components can be made from various materials, including metals like brass, copper, and stainless steel, as well as plastics and rubber seals. Choosing a grease compatible with the materials used in your plumbing system is essential to prevent damage, corrosion, or deterioration over time. Some greases may contain additives or chemicals that can react adversely with certain materials, leading to degradation or failure of components.

By selecting a grease specifically formulated for compatibility with the materials in your plumbing system, you can ensure optimal performance and longevity while minimizing the risk of costly repairs or replacements.

How To Apply Plumbing Grease

Once you have identified the plumbing grease suitable for your application, the next step is to apply the lubricant to the connection point. Before applying the plumbing grease, we recommend thoroughly cleaning and drying the surface. Any debris or moisture present can form a barrier between the grease and the surface, diminishing the former’s effectiveness.

When it comes to applying plumbing grease, less is often more. Using your fingers or a small paintbrush, apply a thin layer of grease to the connection point. You will want to avoid applying too much; any excess will push out as you join the fittings.

Plumbing grease is a vital component in maintaining and prolonging the lifespan of plumbing systems. By choosing the right type of grease and applying it correctly, you can prevent corrosion, protect rubber components, and ensure smooth operation of your plumbing fixtures.